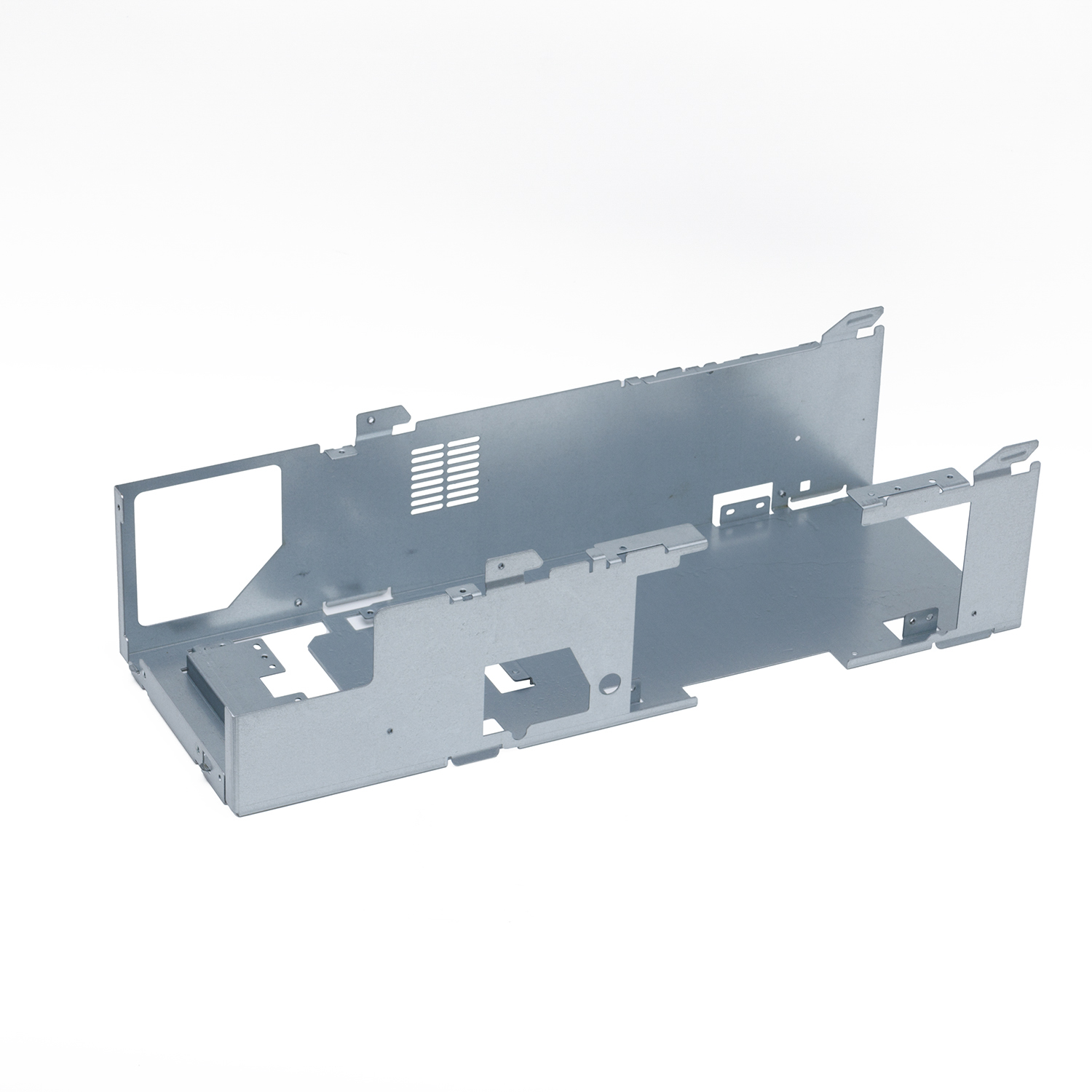

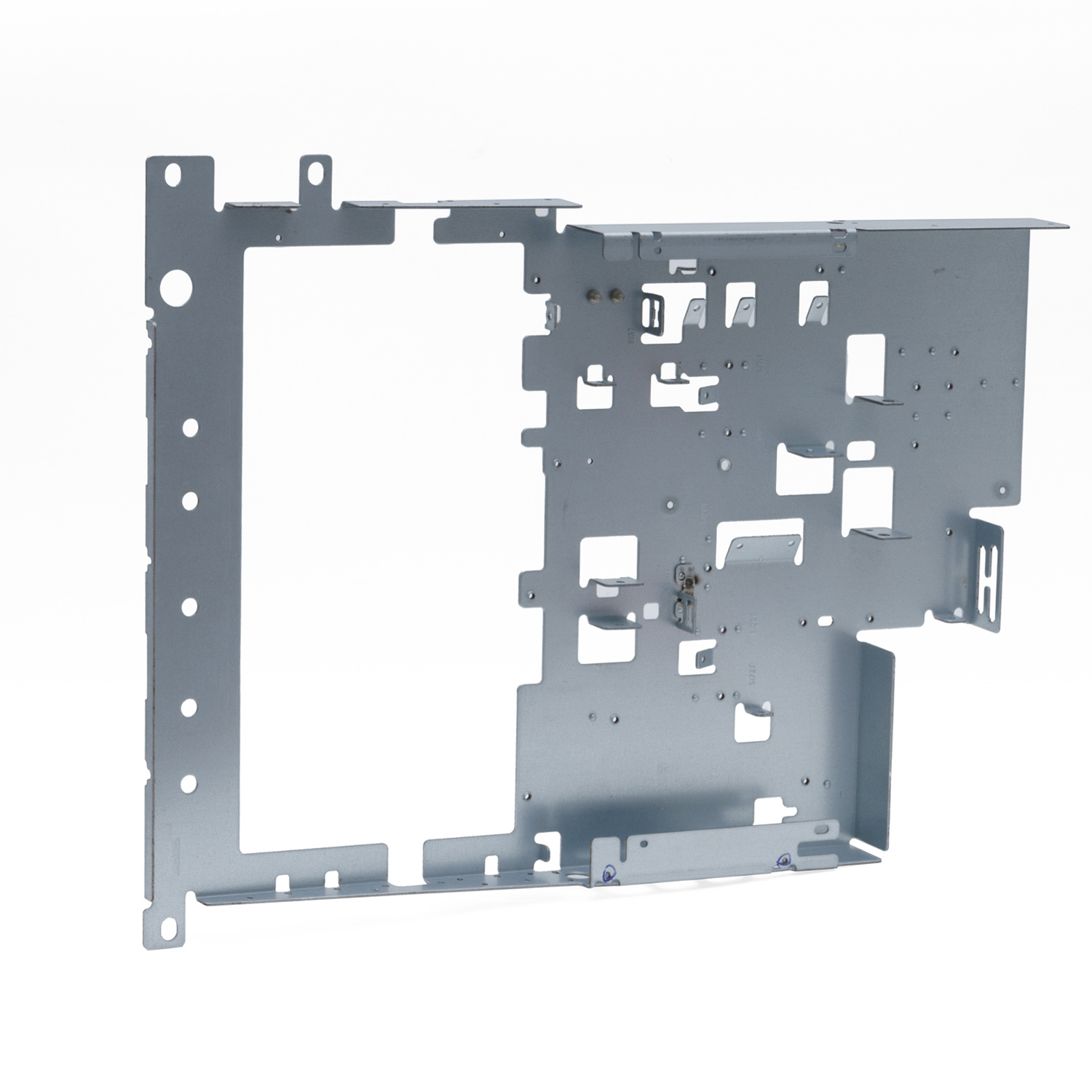

Hot rolled sheet metal processing parts

The hot-rolled sheet metal processing part shown is a reaction plate base designed by Chengruifeng Company for the feedback module of high-end medical equipment. Chengruifeng Company fully assists medical equipment enterprises in cabinet research and development, product structure optimization, and customized production solutions. This article mainly presents the parameters, process, and some common problems of the component from multiple aspects.

Product Features

This component has the following characteristics:

(1) 6000W laser cutting equipment processing, smooth cutting surface, high accuracy;

(2) The surface has been galvanized, making it beautiful and durable;

(3) 2.5mm thick, sturdy and heavy, suitable for the height requirements of medical equipment for balance;

(4) Customized production, product upgrades and changes can be adjusted at any time;

Note: At the bottom of the page, there are more detailed product photos to showcase the product characteristics of the hot-rolled sheet metal parts.

Product parameters

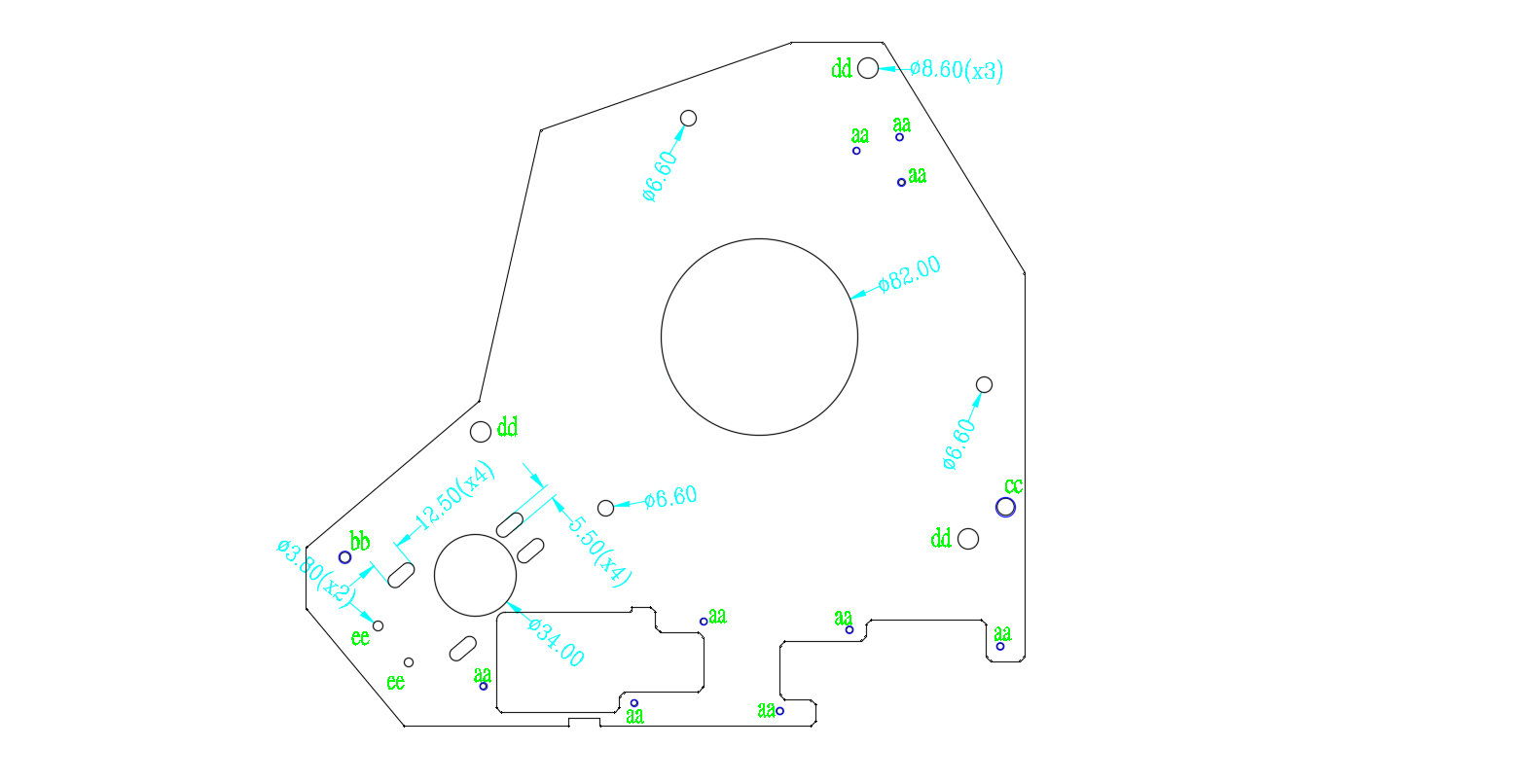

| Product size | 300*285.4*2.5mm | Unfolded Size | 300*285.4*2.5mm |

|---|---|---|---|

| Product materials | SPHC | Thickness | 2.5mm |

| Surface Treatment | Environmentally friendly colored zinc (film thickness 7-10UM) | processing difficulty | same as |

| Dimensional error | ±0.3mm | angle error | ±0.5° |

Product drawings

Process

| Serial Number | Technology | Process Description and Precautions |

| 1 | Laser cutting |

The thickness of this product reaches 2.5mm, and the laser cutting process can more effectively control the specified shape, quantity, and quality of hot-rolled sheet metal parts. This process is closely related to the dimensional tolerance of the product; |

| 2 | chip removing |

Remove the burrs or burrs from the processed flat sheet metal parts, and the height of the burrs must be controlled below 0.2mm; |

| 3 | reaming |

Prepare for the subsequent tapping and punching process, and control the diameter error of the circular hole; |

| 4 | Attack teeth |

13 places need to undergo tooth tapping treatment to prepare for subsequent assembly; |

| 5 | Surface Treatment |

The surface is coated with colored zinc, with a film thickness requirement of 7-10um; There should be no scratches on the surface; |

| 6 | sizing |

This product is applied to medical equipment and has extremely high requirements for surface plane amplitude, with amplitude error controlled within 0.1mm; |

| 8 | Quality inspection |

Thoroughly inspect the quality requirements such as dimensional errors and surface scratches of the processed products; |

| 9 | package |

Hot rolled sheet metal parts have a dedicated packaging scheme designed by packaging engineers, aimed at maximizing the avoidance of collision deformation and surface scratches during subsequent operation of the product; |

Frequently asked question

1. Describe the differences between hot-rolled sheet metal parts and cold-rolled sheet metal parts

As is well known, the production processes of the two raw materials (cold rolled sheet and hot rolled sheet) are different. Hot rolled steel plates are rolled at high temperatures, while cold rolled plates are rolled at room temperature.

Therefore, cold rolled sheet metal parts have a relatively higher hardness and greater processing difficulty, but are not easily deformed and have considerable strength, and are often used in the production of product shells. However, hot-rolled sheet metal parts have low hardness, easy processing, and good ductility. Under the same strength, the thickness of hot-rolled sheet metal parts will be thicker, which is more commonly used in the production of product chassis.

2. There are several surface treatment methods for stainless steel sheet metal parts

A surface treatment: The raw material surface of hot-rolled plate is relatively rough and has average anti-corrosion performance, so surface galvanizing or spraying can be carried out to improve its aesthetic performance and service life;

B Cutting mode, Laser cutting is more often used, and the smoothness of the cutting part can also be higher, but attention should be paid to the use of laser power, and the formation of slag spots at the cutting place should be placed;

3、Which company is better at processing hot-rolled sheet metal parts?

Shenzhen Chengruifeng Technology Co., Ltd. has been focusing on sheet metal processing for 23 years, accumulating experience in product design and production in multiple fields. Currently, it has over 80 product engineers and is a strong sheet metal processing enterprise.